Composites

Composite Manufacturing Processes

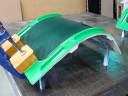

Bellmont employs a range of composite manufacturing processes depending on the customer requirements, design, functionality, volume, finish requirements to A and,or, B side surfaces. These processes include open moulding using hand lay up, spray up, vacuum bagging, and closed moulding processes including vacuum infusion and RTM light.

Post Finish

Bellmont's expertise in Component painting, particularly composites, is highly regarded by the major Automotive companies. Our ability and thorough understanding of post painting composites make Bellmont the ideal choice for end users selecting a manufacturer to make their composite parts. This provides comfort to you the customer with the knowledge your painted composite part is produced and painted by the same company who takes full responsibility for the part from composite manufacture through to the fully completed painted part.

Post Assembly of Composite Parts

Another key capability is Bellmont providing a huge range of post assembly on your composite parts. This can include electronics, bracketry, fasteners, lock systems, hinging systems, etc. This, including the capability to embed a range of products during composite manufacture, can also offer significant customer labour savings during its' final assembly.

Bellmont can also offer design, modification, manufacture and supply of specialised hardware, bracketry, fittings, wiring paths, mechanical & electronic systems and componentry.